Best Price - Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine Very Recommended

Compareand - Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine Best Price

Application:

500*455mm

Model Number:

SMT880

Number of feeder:

80

Number of camera:

10

Number of head:

8

Guide:

Guide Screw

Automatic board:

Three-stage track

Software:

English

Drive motor:

Panasonic Servo Motor

MAX circuit board area:

500*455mm

Applicable Components:

0201 0402 0603 0805 1206 diode audion SOT QFP

Maximum mounting speed:

15000 Pcs/hour

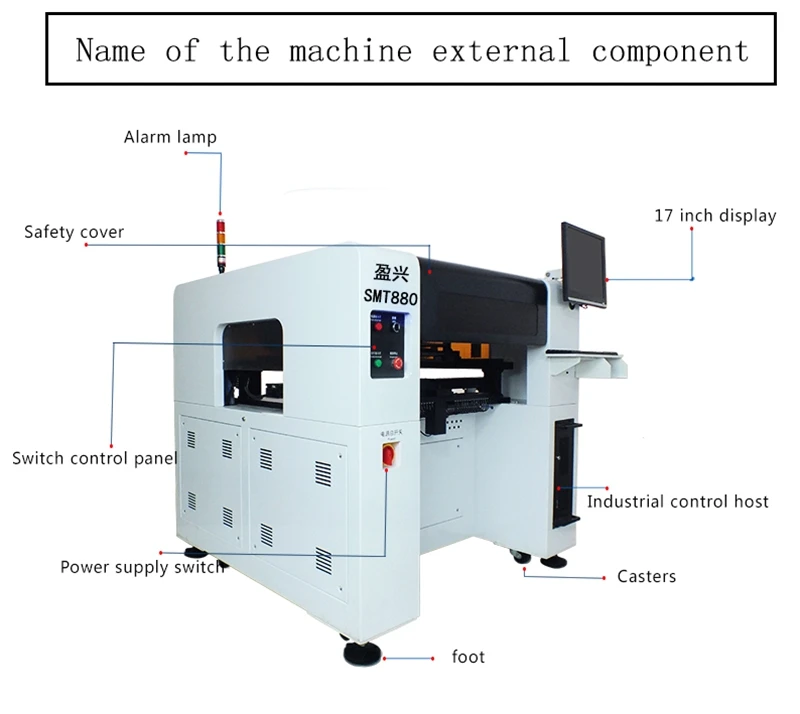

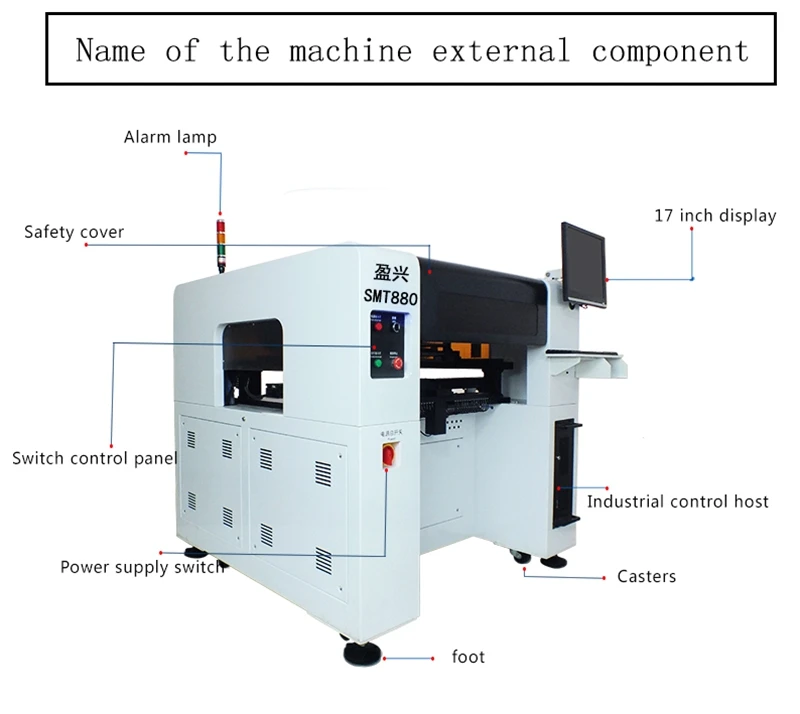

1.Details

2.Technical Parameter

| Specification | |

| Number of feeders | 80 |

| Number of IC tray | 8 |

| Number of cameras | 10 |

| Number of heads | 8 |

| Average power | 1000W |

| Automatic board | Three-stage track |

| Guide | Screw guide |

| Maximum mounting speed | 15000 Pcs/h |

| Average mounting speed of actual mounting resistance | 12000 Pcs/h |

| Maximum travel scope in Z axis | 20mm |

| Maximum circuit board area | 500×455mm |

| Positioning precision | 0.01mm |

| The buffer range of suction nozzle | 4.5mm |

| Weight | 600KG |

| Dimension | 1420*1370*1350mm |

| Power supply | 110V/220V, 50/60Hz |

| Compressed air | 0.5-0.6Mpa |

| Drive motor | Panasonic servo motor |

| Motion drive system | Panasonic high-speed DSP drive |

| Recognition mode | Simultaneous recognition of eight heads |

| Vacuum source of suction nozzle | High-speed on-off vacuum generator with vacuum breaker |

| Operating system | Full-automatic chip mounter operating system operating system. |

| Independently developed by us based on Windows operating system | |

| Supports windows xp, win7 | |

| Element angle | 0-360°synchronous rotation during movement |

| X/Y operation mode | Intelligent curve of the linear acceleration and deceleration linkage |

| MARK point positioning | Full-automatic (the MARK point can be adjust at will) |

| Intelligent alarm | Automatic correction, automatic filling, feeding shortage alarm |

| Plate entering mode | Automatic connection from left to right in single sections |

| Automatic PCB transfer positioning/plunger positioning, manual plate feeding | |

| Visual display | 17-inch industrial control display, 4:3, resolution: 1280 x1024 |

| Number of recognition cameras | One Mark recognition camera, four quick-recognition cameras |

| One precise-recognition camera. | |

| Adaptive mounting scope | Adaptive to 0201 0402, 0603, 0805, 1206, diode, audion, SOT, QFP |

| Within 40*40mm and the pin distance ≥0.3mm (0.5mm center distance) and BGA. | |

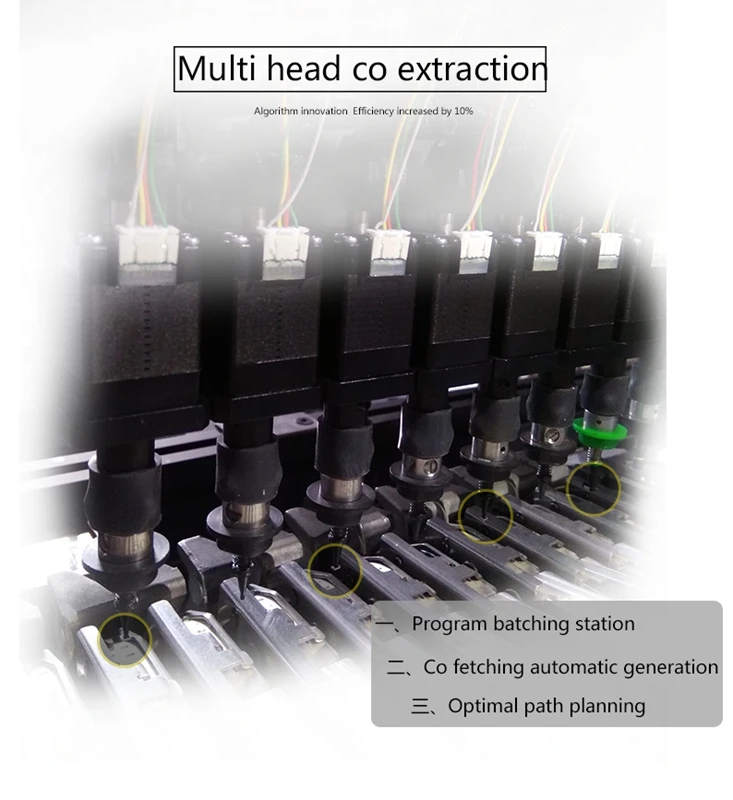

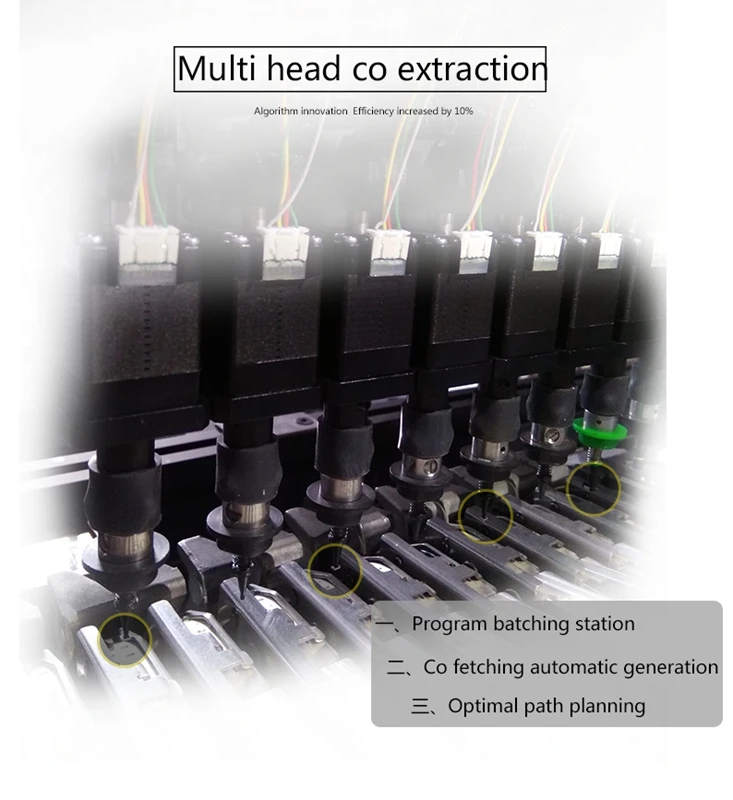

3. 8 Placement Heads

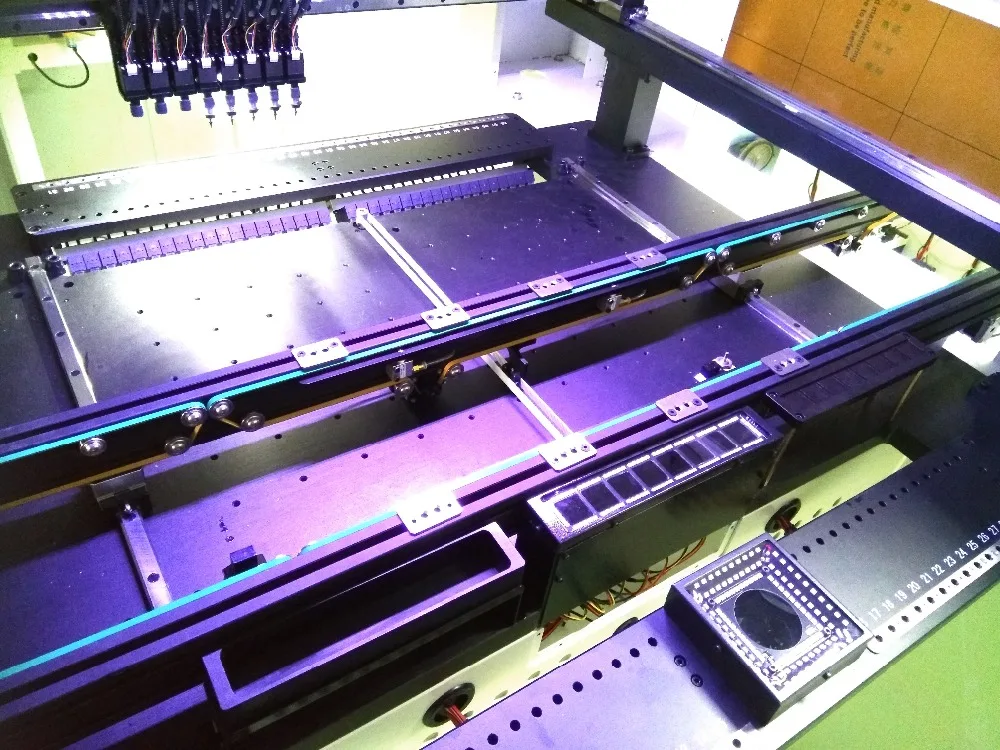

4.Screw

5.10 Cameras+Conveyor

6.Three section track

7.Application area

8.Package

1.Details

2.Technical Parameter

| Specification | |

| Number of feeders | 68 |

| Number of IC tray | 8 |

| Number of cameras | 10 |

| Number of heads | 8 |

| Average power | 1000W |

| Automatic board | Three-stage track |

| Guide | Screw guide |

| Maximum mounting speed | 15000 Pcs/h |

| Average mounting speed of actual mounting resistance | 12000 Pcs/h |

| Maximum travel scope in Z axis | 20mm |

| Maximum circuit board area | 500×455mm |

| Positioning precision | 0.01mm |

| The buffer range of suction nozzle | 4.5mm |

| Weight | 600KG |

| Dimension | 1420*1370*1350mm |

| Power supply | 110V/220V, 50/60Hz |

| Compressed air | 0.5-0.6Mpa |

| Drive motor | Panasonic servo motor |

| Motion drive system | Panasonic high-speed DSP drive |

| Recognition mode | Simultaneous recognition of eight heads |

| Vacuum source of suction nozzle | High-speed on-off vacuum generator with vacuum breaker |

| Operating system | Full-automatic chip mounter operating system operating system. |

| Independently developed by us based on Windows operating system | |

| Supports windows xp, win7 | |

| Element angle | 0-360°synchronous rotation during movement |

| X/Y operation mode | Intelligent curve of the linear acceleration and deceleration linkage |

| MARK point positioning | Full-automatic (the MARK point can be adjust at will) |

| Intelligent alarm | Automatic correction, automatic filling, feeding shortage alarm |

| Plate entering mode | Automatic connection from left to right in single sections |

| Automatic PCB transfer positioning/plunger positioning, manual plate feeding | |

| Visual display | 17-inch industrial control display, 4:3, resolution: 1280 x1024 |

| Number of recognition cameras | One Mark recognition camera, four quick-recognition cameras |

| One precise-recognition camera. | |

| Adaptive mounting scope | Adaptive to 0201 0402, 0603, 0805, 1206, diode, audion, SOT, QFP |

| Within 40*40mm and the pin distance ≥0.3mm (0.5mm center distance) and BGA. | |

3. 8 Placement Heads

4.Screw

5.Three section track

6.Application area

7.Package

Unit Type:

Set

Package Weight:

500.0kg (1102.31lb.)

Package Size:

142cm x 137cm x 135cm (55.91in x 53.94in x 53.15in)

Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine for sale, Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine best price,Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine cheap,Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine cheapest, Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine sale,Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine free pdf,Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine Where To Buy,#Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine Discount,#Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine Review,#Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine compare Price,#Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine Who Sells The Cheapest,#Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine The Cheapest Online,What Is The Best Price For Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine ,#Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine download ebook PDF EPUB, book in Polish language,[download] Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine in PDF format,Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine download free book in PDF format,Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine amazon,Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine Alibaba, Best Reviews Of Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine,Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine epub,Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine Limited Time,Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine Get Now,Buy Made in China automatic pick connected with computer Low noise smd components mounting machine used smt pick and place machine Discount

espresso